Buna n nitrile nbr is a general purpose oil resistant polymer known as nitrile rubber.

Buna n rubber chemical resistance.

Chemical resistance rubber material selection guide nbr nitrile or buna n acrylonitrile butadiene abbreviation nbr astm d 2000 classification bf bg bk chemical definition acrylonitrile butadiene 30000 series physical mechanical properties durometer or hardness range 20 95 shore a tensile strength range 200 3 500 psi.

Minor rubber s extensive compatibility chart will assist in the design and selection of your manufactured rubber product.

Use this rubber chemical resistance chart to make sure that the elastomer or o ring seal you choose will be compatible with the particular environment.

Elastomers natural and syntetic rubbers.

Polyester chemical resistance chemical resistance of polyester to products like acetic acid diesel oil and others.

Trade names include perbunan nipol krynac and europrene this rubber is unusual in being resistant to oil fuel and other chemicals.

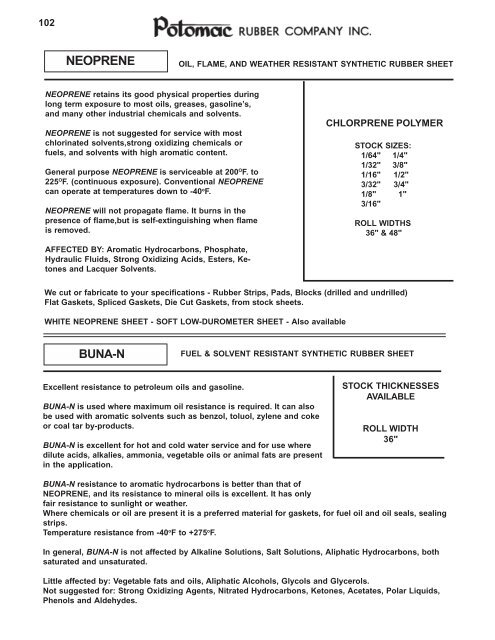

Properties characteristics and resistances.

Nitrile rubber also known as nitrile butadiene rubber nbr buna n and acrylonitrile butadiene rubber is a synthetic rubber derived from acrylonitrile acn and butadiene.

Get information about nitrile polymer including physical mechanical and thermal properties as well as environmental and chemical resistances.

Acetone thermophysical properties chemical physical and thermal properties of acetone also called 2 propanone dimethyl ketone and pyroacetic acid.

Good 225 o f excellent 275 o f excellent 400 o f.

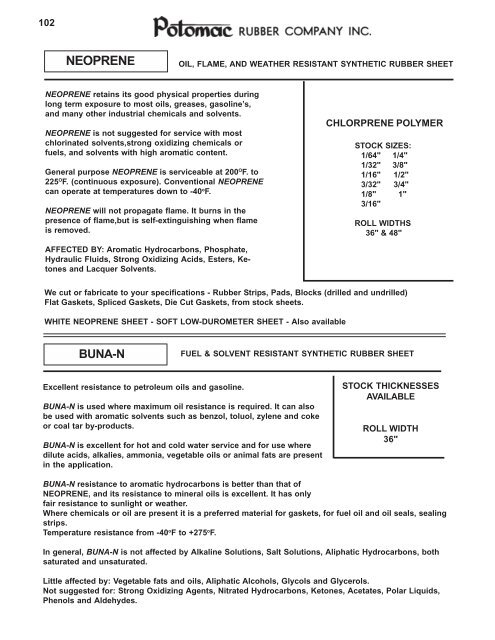

Buna n is a copolymer of butadi ene and acrylonitrile.

Buna n has good solvent oil water and hydraulic fluid resistance.

The chemical compatibility of rubber is extremely important as the rubber can degrade rapidly if the rubber material is not compatible with the environment or media that it comes into contact with.

Ceramag satisfactory to 72 f.

Buna n satisfactory for o rings 5.

Buna n ethylene propylene ep fluoro elastomer viton ptfe.

Basic o ring chemical resistance compatibility information is based on isolated generic o ring material testing in optimal conditions at room temperature and pressure.

Exposing rubber o ring materials to multiple chemicals and compounding application factors like temperature pressure and gland design can result in significantly different performance.

It displays good compression set abrasion resistance and tensile strength.

Chemical resistance data these recommendations are based upon information from material suppliers and careful examination of available published information and are believed to be accurate.